|

Classic straight blade plugs and sockets |

| Classic material can still be found when

old homes are renovated. Examples, including clock

outlets are shown below. Moreover radio outlets

are added. They look like

125V sockets, but had a very different use A few images of knob and tube wiring have been added also; a type of wiring that still can be found old homes. The origin of US flat blade plugs is described on a separate page. |

| Rating: Sockets and plugs may have two different ratings for amperage and voltage: 15A

- 125V and 10A - 250V.

This has to do with a peculiarity of

the National Electrical Code from 1923 to the 1950s. |

Originally,

domestic sockets were rated at 10A - 250V, because the NEC limited lighting circuits to 10 Amp. In 1923, the code changed to allow lighting circuits to be fused at 15 Amp. However, the old rule (10 Amp) still applied to circuits over 125 volts. |

|

|

|

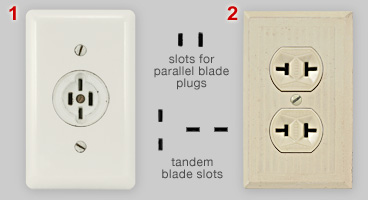

| 1, 2 | Two

examples of

classic

non-grounded sockets with slots for plugs with two parallel blades

and for plugs that have blades in tandem orientation. Both types

of plugs

have

been designed by Harvey Hubbell. The tandem blade configuration was

patented in 1904, the parallel version eight years later. The page on origin of US plugs gives detailed information. For many years both types were available, but finally the parallel orientation became the standard US 15A - 125V plug. The coexistence of parallel and tandem blade plugs necessitated the construction of wall sockets that could accept both types. Manufacturers: General Electric (no. 1), and Hubbell Inc. (no. 2). Sockets became available during renovation of a 1937 home in California. {BN} Leviton is the only company that still makes socket no.2 for repair use only (info given by Jan de Bondy, Canada). |

| 3 | Dual socket that accepts not earthed plugs with

either parallel or tandem blade plugs. Rating: 10A - 250V / 15A - 125V. Socket nos 3 and 4 have been found in a home build in 1905 in the province of Québec, Canada,. Home was connected to mains later. {TH} Manufacturer: Canadian General Electric; the Canadian counterpart of the US-based General Electric. Both companies use the same logo (see top inset). Socket has a Canadian Standards Association (CSA) mark, see bottom inset. Because of the CSA mark, the socket must have been made after the introduction in 1953. |

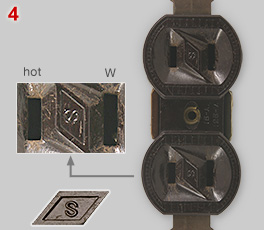

| 4 note |

Dual

socket for not earthed plugs with parallel blades. Rating: 15A - 125V. Manufacturer: former (1919 -1992) Canadian company Smith & Stone Ltd. {TH} Dating: early 1940s - early 50s, because it doesn't have the CSA mark (see no. 3) that was introduced in 1953. The museum is grateful to Jan de Bondy for providing detailed information about manufacturer and dating. The socket is polarized. Left slots (hot = line) are 7.12 mm wide, right while slots (White = neutral) are 8.72 mm wide, see inset. Socket nos 3 and 7 have similar polarized outlets. |

|

|

|

|

| 5 | Standard flat blade plug and connector made of ebonite, a

vulcanized natural rubber. A

relative high sulfur content and prolonged times of vulcanizing

results in a solid product. Connector rating: 15A - 125V / 10A - 250V. Manufacturer: Arrow Electrical Wiring Devices. Dating: ca. 1930s. {ChR} |

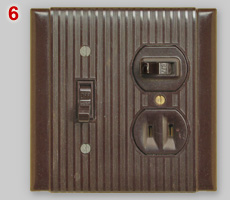

| 6 | Classic

model of a not grounding socket, with switch, rated at 15A - 125V. The

switch

left is an additional light switch. Nowadays only grounded sockets are allowed, but non-grounded plugs (NEMA 1-15P) are still permitted for appliances that don't require an equipment ground connection. Manufacturer: Leviton. US patent no. 2704832 was granted on March 11, 1955. |

| 7 | Monolite

quintet socket, rated at 15A-125V / 10A-250V. Manufacturer: Monowatt Electric Corporation, New York, Providence, Chicago. Socket dates back to late 1930s, when Monowatt was a division of General Electric. {RP} Socket nos. 7 and 8 came in their original carton. They are shown on a separate page. |

| 8 | 4-plug

socket,

rated at 15A - 125V. The dual - duplex design probably dates back to

the

mid 1950s. Manufacturer: General Electric (wiring device department, Providence). {RP} |

|

|

|

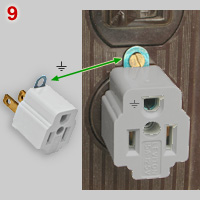

| 9 | US ground adapter for 15A - 125V two pole socket. The grounding clip of the adapter (green arrow) is connected to earth via the brass screw that is used to attach the wall plate to the body of the socket (which have to be grounded !). These adapters are also known as cheater plugs. In 2003 they were still available in some hardware stores. |

| 10, 11 |

Obsolete plug with two flat blades in T-configuration, rated at 10A - 250V. The plug don't fit in socket no. 2 and is incompatible with NEMA 2-20 sockets, because of different pin spacing (see image no. 11). Manufacturer of the shown plug is not indicated; it could have been made in Australia, since a similar type has been used also in Australia and New-Zealand in the 1930s - 1950s. {ChR} |

|

|

|

| 12 | Non-NEMA

duplex

socket with angled slots for line (hot) and neutral (w). It is rated at

15A - 125V

and 10A - 250V. The two sockets are each other's mirror image, an unusual orientation, but the top and bottom angled slots are correctly (crisscrossed) wired. Manufacturer: Hubbell Inc. (model 7051). |

| 13 | Hubbell

10A-250V, 15A-125V plug that fits in socket no. 12. The type of plug

with angled power pins is described in more detail on the origin of US flat blade

plugs page. The plug has an

Underwriters Laboratories* certification mark. Dating; probably 1950s. * U.S. testing facility and developer of safety standards. |

| 14 | Dual

socket with not earthed outlet for parallel and tandem plugs and

earthed outlet for plugs with angled power pins, a now obsolete type

designed in 1915 by George P. Knapp (Hubble Inc.). See images 12 and 13

for details. Image of socket has been taken by Bryce Nesbitt in a building slated for demolition in Berkeley CA. Manufacturer: Hubble Inc. Dating: 1930s. |

|

|

|

| 15 | Tap-A-Line outlet with elongated slots to receive the blades of multiple appliance plugs. Details are given on a separate page. |

| 16 | Pull

chain medium

size*

light bulb socket with two non-grounded outlets. Only the lamp is

switched

on/off by the pull chain; outlets are continuously active. * medium refers to the diameter of the Edison screw base; medium = 26 mm (U.S.), or 27 mm (Europe). Size are also indicated as E26 and E27. The adapter has been made in Colombia |

| 17 | Two

medium size

light bulb

adapters. Left: screw base to 2-pole outlet*. Right:

non-grounded 15A - 125V plug to medium light bulb socket.

Manufacturer:

Leviton, Melville, New York. * screw base outlets date back to a 1904 Hubbell patent, see origin of US flat blade plugs for details. An original Hubbell separable attachment plug and other examples of screw based outlets are shown on a separate page. |

|

|

|

| 18 | Both

General Electric Company and Academy Electrical Products Co. (later

part of Eagle Electric and therafter Cooper Industries) have designed

plugs and connectors with an automatic wiring method; tools are not

needed. Details about three automatic wiring methods are given on a separate page. These plugs date back to

the early 1950s; some are still available. |

↓ note |

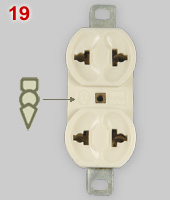

Nos. 19 and 20 have been made for the U.S. Army in Germany. They were for sale in Germany in the 1950s to ca. '80s. |

| 19 | Not earthed duplex socket with

slots in parallel and in tandem position, rated at 15A - 250V (see also

no. 2). Slots accept also not earthed

continental European

2-pin plugs with 4.0 or 4.8 mm pins. Original wall

plate is missing. Manufacturer: Busch-Jaeger in Lüdenscheid, Germany.

The socket has a type of Busch-Jaeger logo that has been used from 1951

until 1979. {FSE} |

| 20 |

Adapter plug for NEMA 5-15 plugs (image

left) that fits in Terko* sockets

(image right).

Note that NEMA 5-15 is a 120 Volt standard whereas the German Terko

system is rated at 250 Volt. The adapter does not have a transformer. The adapter has a MPAD molding mark. No. 76 refers to the company that has produced the cast: Bezet-Werk, Herman Buchholz GmbH in Berlin-Lichtenrade. No. 131 stand for an urea-formaldehyde resin with cellulose as filling agent. It is not clear whether Bezet-Work also has assembled and sold the adapters. {FSE} * See Terko page for details. |

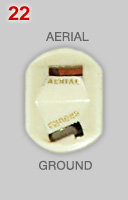

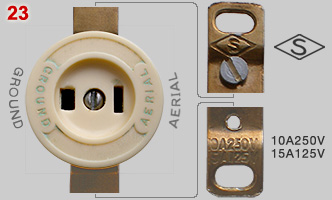

| Radio

outlets In many homes, build in the 1920s to '40s radio antenna coils were installed at the attic. A wire connected the antenna to a grounded radio outlets in rooms downstairs. When home antenna coils fell into disuse, radio outlets were often put out of sight by wall paper or layers of paint (see image No. 21). |

Although radio plugs had a pin configuration that never has been used for 120 or 240 Volt power connections, it is confusing that often radio outlets were part of a dual socket; the other half was a standard 15A-120V outlet. |

|

|

|

| 21 | Radio outlet made by Hart & Hegeman in

Hartford, Conn. H&H merged in 1928 with the Arrow Electrical Company to become the Arrow-Hart & Hegeman Electrical Co. Photo has been sent by Joshua Hodges. The dual socket has a radio and NEMA 1-15 socket. |

| 22 | Radio outlet designed by Victor R. Despard. Patent application was filed in 1932 by Pass & Seymour Inc. in Syracuse, N.Y. Outlet has been made also by Bryant Electrical Corporation in Bridgeport, CT. |

| 23 | Radio outlet found in a 1940 apartment

building (a former hotel). The image is based on photos taken by John

Bardy, Los Angeles. The two parallel outlets resemble a regular 15A-125V socket and the copper strap indicates 10A-250V / 15A-125V. However a NEMA 1-15 plug doesn't match because the GROUND outlet is smaller than the regular hot wire opening. The other end of the strap shows a diamond with character S. A similar logo was used by the Canadian electro-technical company Smith & Stone Ltd (see image 4, above and manufacture details). The radio clock is either S&S made, or standard S&S straps have been used to mount an unknown radio outlet. |

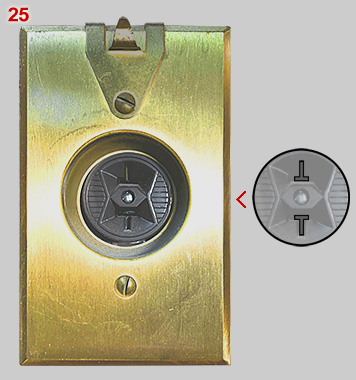

| Clock outlet A clock outlet is a receptacle recessed into the wall. A hook on top which allows a clock to hang from it. Classic clock outlets - shown below - were designed for a special small type of plug with T-shaped pins. The plug was wired to the clock. |

Recessed wall outlets still exist. Nowadays models accept standard NEMA 5-15 plugs (5A-125V). Among others they are used to plug in a flat screen TV right behind the wall. |

|

|

24 Clock outlet made by Arrow Electrical Wiring Devices, Hartford, Conn, USA. Outlet has been found in a home build mid 1950s in Jackson, Miss. USA. 25 Clock outlet made by Harvey Hubbell Inc, Bridgeport, Conn. USA. Both images are not part of the museum collection., but based on photos taken by • Genevieve Collins (image 24), and • Dr. Amber Brown (image 25). The drawing of a classic clock socket shows the two T-shape plug inlets. |

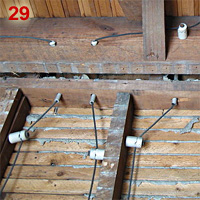

| Knob and Tube wiring (K&T) Knob and tube wiring was an early standardized method of electrical wiring. It used individual wires supported by porcelain insulators (knobs) and run inside porcelain cylinders (tubes) when going through wood beams. See image nos 23 - 26. Until the mid-1930s, knob-and-tube wiring was installed in many U.S. homes and it can still be found in some older houses. |

Whether

or not K&T has to be replaced is discussed on several web

sites. See for

example: httpsss://www.nachi.org/knob-and-tube.htm and https://diy.stackexchange.com/a/20279/5960 In short: knob and tube wiring, properly installed and in good condition is both reliable and safe, but it has no ground wire and is not appropriate for electrical equipment that requires grounding. K&T is not permitted in new constructions in the US, except in a few industrial and agricultural related situations specifically listed in the US National Electrical Code. |

|

|

|

|

| 26, 27 | Porcelain

knob

insulator. This example consists of two pieces and has on each side of

the nail a pass-through groove to guide the wire. Knobs are nailed into

wall studs and floor joists.

Usually hot and neutral wires are separated from one another, which

allows the wires to readily dissipate heat into free air. Therefore

wires are capable of carrying higher currents than the same conductors

in close proximity. Another type of insulator (not shown) consists of a

single piece of porcelain. The wire loops in a circular groove running

around the circumference. Also block-shaped ceramic cleats are

occasionally used. {BN} |

| 28 | Porcelain

tube, used to keep wires from coming into contact with, or being

compressed by wood framing parts of a building. {BN} |

| 29 | K&T wiring inside a 1930 Pittsburgh house. Part of a photo taken in 2006 by Laura Scudder and shown at the Wikipedia page about knob and tube wiring. |